Copyright © Wuxi Mingcheng Transmission Technology Co., Ltd. All Rights Reserved.

Google Analytics Technical Support:NSW

1. Blending Rubber

Each tire can contain up to 10 different rubber blends.

The blend determines the subsequent characteristics of various tire components. In addition to rubber and fillers, numerous chemical additives are heated and combined with one another as activators and blending aids etc.

Technical Requirements of the belts

Conveyor belt must be exceptionally robust and resistant to incisions, have good release properties and be able to withstand the chemical additives. In some blending processes, water has to be conducted away via the belt.Directly after the blending process, the finished blend has to be conveyed at a product temperature of up to 175°C.

2. Batch-off

Feeder belts convey the hot rubber sheet from the compounding facility into a dip tank. The sheet is brought up to ambient temperature in the cooling section. A pendulum places the material on pallets in specified batch lengths/weights.

Technical Requirements of the belts

The sheet is conveyed at large angles of incline (in some cases vertically) in front of and behind the cooling section. In addition to chemical resistance, good release properties and exceptionally good grip are vital at this step in the process. When the rubber is immersed in the dip tank, the belt needs to be consistently waterproof and have a large open area.

3. Extrusion and Cooling

Two very different sub-processes come together at this step of the process. First of all, the rubber sheet is extruded and injected through dies in defined cross sections from which tread and sidewalls are made later on. After passing through a cooling tray, the strips are either cut to length ready for tire building or rolled up.

Technical Requirements of the belts

The various sub-processes require the belts to have specific characteristics. Some feeder belts to the extruder must be suitable for metal detectors. Behind the extruder, the belt needs to be able to withstand temperatures right up until cooling tray and have good release properties, it must also be possible to use it under water and be exceptionally resistant to incisions.

4. Calendering

The calendering process produces the tire’s inner liner and its carcass. The material (the inner liner or the carcass with the fabric/steel cord positioned between two layers of rubber) is heated up and rolled to the requisite thickness. After passing through a cooling section, the strips are either cut to size ready to build the tire and stacked or rolled up.

Technical Requirements of the belts

Good release properties and superior resistance to temperatures are vital for this process. The cutting process requires belt material that can withstand incisions.

5. Cord Cutters

For the tire carcass and steel belt, textile fibers or steel cords are covered with a layer of rubber during the calendering process. A strong bond between these materials is vital to ensure that the tire is safe to drive on and performs well. The components are either cut to size ready for tire building and stacked or rolled up.

Technical Requirements of the belts

Good release properties and superior resistance to incisions are required at this step in the process. Furthermore, because the components are cut to size accurately, the belts need to be able to retain their dimensions and offer good grip in order to achieve exceptional positioning accuracy.

6. Tire Building

The prefabricated components are used for tire building. They are either assembled manually or automatically on a drum. The tire is then ready for vulcanization that turns it into an elastic and durable product.

Technical Requirements of the belts

In addition to good release properties, automatic positioning of each of the tire components requires excellent dimensional stability and grip. This is the only way of ensuring precise positioning. Because space is at a premium, only small return diameters are often possible.

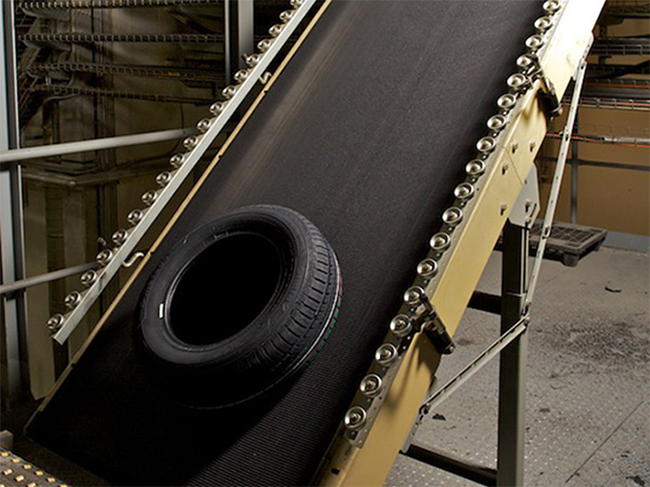

7. Vulcanization

The uncured tire is vulcanized under heat and pressure in a curing mold. In the process, the tire components combine to form an elastic and resilient unit. The tread is formed in this process.

Technical Requirements of the belts

Exceptionally robust belts are required for feeding in and discharging the tires. As the haul-off belts also act as a cooling section, they need to be able to withstand temperatures > 100°C.

8. Inspection and Storage

After checking the quality of the vulcanized tires, they’re stored in the dispatch warehouse where orders are then assembled. Tires are often conveyed individually to start with and then stored on pallets on high-bay storage systems.

Technical Requirements of the belts

Tire handling includes the typical functions encountered in logistical processes: horizontal, inclined and accumulation conveying as well as pushing goods on and off belts from the sides. In addition to a robust belt design and superior tensile strength, various surface characteristics and friction coefficients are required. Considering the high number of goods taken to and removed from storage daily, the entire operation needs to function smoothly.

MINSEN is a conveyor belt manufacturer. The company is located in Wuxi, located on the beautiful shore of Taihu Lake, east of Shanghai-Nanjing Expressway, north of Beijing-Shanghai High-speed Railway, only 10 minutes from Wuxi Airport.

The substrate belt belongs to the plane high-speed transmissionbelt. Usually, the substrate belt has a base layer of nylon in the middle, andthe surface is covered with rubber, cowhide and fiber cloth. It is divided intorubber nylon sheet base band and cowhide nylon sheet base band.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.