Copyright © Wuxi Mingcheng Transmission Technology Co., Ltd. All Rights Reserved.

Google Analytics Technical Support:NSW

1. Check-In: Items of baggage are placed on check-in systems for conveying where they are weighed and labeled/coded. The coding clearly identifies where they are during the conveying process. Check-in conveyors are often designed with a slight incline.

1. Check-In

Items of baggage are placed on check-in systems for conveying where they are weighed and labeled/coded. The coding clearly identifies where they are during the conveying process. Check-in conveyors are often designed with a slight incline.

Technical Requirements of the belts

The belts must be able to prevent items of baggage from rolling down again on inclined sections and when conveyors are operating in stop and go mode. The surface pattern and belt fabric must be robust due to the vast number of items of baggage placed on the belts, by trolley suitcases for instance, at high concentrated loads.

2. X-ray Machines

Security has top priority at airports. Which is why all items of baggage are checked by x-ray equipment to ensure they contain nothing that could jeopardize flight safety. This has applied for some years to both carry-on items and baggage that’s put in the hold.

Technical Requirements of the belts

During the screening process, neither the belts nor the splice must cast a shadow. In order to prevent anything being out of focus on the x-ray image, the belts must be absolutely flat and track in a straight line through the x-ray equipment at the same speed.

3. Accelerated and Inclined Conveying

Accelerated and inclined conveying must prevent as much slippage as possible. If an item of baggage shifts it might no longer be possible to establish its exact position on the conveyor. Should this happen, it can cause major disruptions to the process.

Technical Requirements of the belts

The belts are expected to have long service lives because they are in constant operation. Surface materials and patterns must be designed so that items of baggage can virtually consistently keep to their original position on the belt.

4. Horizontal Conveyors

Items of baggage are often conveyed horizontally over long distances from check-in to the sorter and then for loading onto the plane. To cover these distances, a high proportion of total energy consumption is required by the conveyor.

Technical Requirements of the belts

Flame-retardant EN 340 belts are normally a must in these cases. Further requirements transpire depending on actual lengths of conveyors and other parameters (for example, superior durability, low energy consumption and low noise emissions).

5. Drag Band Conveyors / Twin Belts

Particularly in high-speed areas, items of baggage are conveyed in tubs to make handling easier. These tubs are placed on the outside on two narrow conveyor belts that operate parallel to one another. These drag band conveyor systems achieve speeds of up to 12 m/s.

Technical Requirements of the belts

The fast conveying speeds require undersides that operate smoothly and are durable. At the same time, the coating materials and patterns on the top face have to ensure that empty and heavy baggage tubs can be conveyed without slipping. Due to relatively long conveyors and heavy loads, the narrow conveyor belts are

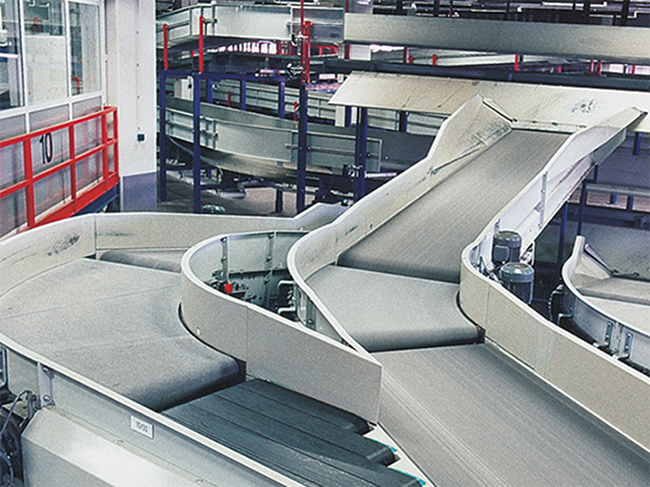

6. Curved Conveyors

Curved conveyors change the direction in which items are moved on the conveyor itself. Common curve angles are 30°, 45°, 60°, 90°, 135°and 180°. They are usually fitted with conical and sometimes cylindrical drive and return drums.

Technical Requirements of the belts

The key criterion for curved belts is an even distribution of force in the fabric in all directions (lengthways, crossways and diagonally) to ensure the belt tracks without any creases and bulges. The belt has to be made of exceptionally tear-resistant fabric because in many applications the profiles sewn on to the outside radius have to absorb all the force directed at the middle of the drum, the purpose of which is to center the belt. Belt surfaces with a high friction coefficient are required at fast speeds.

7. Merging and Discharging

The sorter lies at the heart of the baggage conveyor. All items of baggage checked in are merged in here and (depending on their destination) also discharged again at defined points. Processes to merge baggage in and discharge it often take place at a 30°or 45°angle to the sorter’s conveying direction. The conveyors either have one single wide conveyor belt (full belt conveyors) or several narrow belts that run in parallel in a set (strip merges).

Technical Requirements of the belts

Both designs require the belts to have high friction coefficients on the surfaces in order to ensure baggage is transferred to or taken off the sorter without slipping.

Tight returns are used on full belt conveyors to generate the angle for merging items in or discharging them. Which is why a high level of lengthways flexibility is required from the belts. The coating materials must be able to withstand the temperatures generated by friction and creep.

In the case of strip merges, all belts operating in parallel in a set are stretched with just one tensioning roller. In order to achieve standard tension, compliance with tight length tolerances is a must.

8. Loading and Unloading Aircraft

Aircraft are usually loaded and unloaded by using outdoor inclined conveyors. In the process, the belts convey heavy and sharp items of baggage and are constantly subjected to the typical local weather conditions, which can change significantly.

Technical Requirements of the belts

Conditions such as rain, snow, hail and ultraviolet rays require the fabrics and coating materials in question to be able to withstand weather conditions. A robust, puncture-proof belt has to be able to absorb the high levels of mechanical stress when items of baggage

are thrown onto it. Inclined conveying requires friction coefficients that are sufficiently high to ensure reliable grip.

MINSEN is a conveyor belt manufacturer. The company is located in Wuxi, located on the beautiful shore of Taihu Lake, east of Shanghai-Nanjing Expressway, north of Beijing-Shanghai High-speed Railway, only 10 minutes from Wuxi Airport.

The substrate belt belongs to the plane high-speed transmissionbelt. Usually, the substrate belt has a base layer of nylon in the middle, andthe surface is covered with rubber, cowhide and fiber cloth. It is divided intorubber nylon sheet base band and cowhide nylon sheet base band.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.

Product Name:timing belt Material:Pu, rubber Color:white, black Specification:customized Processing and customization:Yes. Application:mechanical manufacturing.